There are many options to help your employee who consistently performs below-average. To address poor performance, the first step is to identify the root cause. You may have to place restrictions or contractual terms on the employee's employment if the cause is a lack in skill. Another option is to terminate the employee for displaying poor performance that may cause irritation to other members of your team. Either way, you may waste time and resources attempting to resolve the problem.

Managing poor performance

Management of poor performance can be a frustrating and time-consuming task for managers. Managers should be as specific and detailed as possible in identifying reasons that lead to poor performance. While it is tempting to label a poor performer as "unproductive" or "not doing their job," this is often too vague to deal with. A more precise definition of poor performance, such as "not meeting sales targets", is better and more efficient. Other factors that can contribute to poor performance are the employees' work environment, lack in training, and limited resources.

Management classes can help managers understand how to handle a poor performer. An effective process starts with a thorough review of an employee's work performance and collects data that will help identify the problem.

Understanding the causes behind poor performance

To improve employee productivity, it is essential to identify the root causes of poor performance. Performance problems can result from many factors, such as the employee's motivation, skills, and training. A lack of clear expectations is another reason for poor performance. In these cases, managers should make clear what they expect from their team members, and offer them extra training and mentoring if needed.

Managers can identify the root causes of poor performance and devise strategies to improve performance. Although the causes of poor performance can vary from one another, there are four themes that run through them all. The workplace environment is a major factor in the causes. Employees who are performing below their potential will have little impact on the bottom line.

Identifying the barriers to performance

For your organization's success, it is crucial to identify the obstacles that prevent you from achieving the best performance. Poor performance can lead to low employee motivation, engagement, and poor performance. Also, a great leader will be an example to his employees by being a role model and demonstrating the behaviors he expects. The subconscious often creates barriers to optimal performance that are hidden beneath the surface.

These obstacles can typically be seen by an individual as a lack in formal authority, lack access to data, or any other factors that could be hindering the employee's performance. Once you identify the exact barriers that are hampering employee performance, you can then determine how to remove them. Some solutions include a combination of tools and techniques.

Employees who perform poorly are dismissed

Poor performance can lead to many problems. This can damage relationships and decrease employee engagement. It can also have negative long-term consequences for an organization's culture. Moreover, dismissals based on poor performance must be based on an objective and fair reason.

A violation of company policies can often justify dismissal for poor performance. One example is if an employee has posted inappropriately or damaged the company's image on social media. It is possible that they have also checked their personal accounts outside of work hours. Employers should remind employees about these policies. If they don’t comply, further drastic measures may be required.

FAQ

What is Six Sigma, exactly?

It is a way to improve quality that places emphasis on customer service and continuous learning. The goal is to eliminate defects by using statistical techniques.

Motorola invented Six Sigma in 1986 as part its efforts to improve manufacturing.

This idea quickly spread throughout the industry. Today, many organizations use six sigma methods for product design, production and delivery.

What are the 5 management processes?

Planning, execution, monitoring and review are the five stages of any business.

Planning involves setting goals for the future. This includes setting goals for the future and defining what you want.

Execution happens when you actually do the plan. You need to make sure they're followed by everyone involved.

Monitoring is a way to track progress towards your objectives. Regular reviews of performance against targets, budgets, and other goals should be part.

Reviews take place at the end of each year. These reviews allow you to evaluate whether the year was successful. If not then, you can make changes to improve your performance next year.

After the annual review is complete, evaluations are conducted. It helps to determine what worked and what didn’t. It also provides feedback regarding how people performed.

What are management principles?

Management Concepts are the management principles and practices that managers use in managing people and resources. They cover topics like job descriptions (job descriptions), performance evaluations, training programmes, employee motivation and compensation systems.

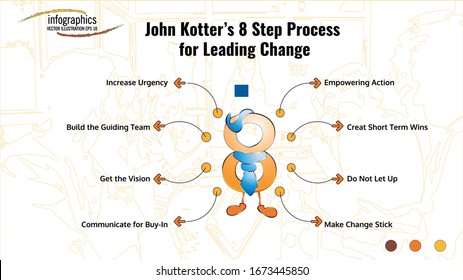

What are the steps in the decision-making process in management?

The decision-making process for managers is complex and multifaceted. This involves many factors including analysis, strategy and planning, implementation, measurement and evaluation, feedback, feedback, and others.

It is important to remember that people are human beings, just like you. They make mistakes. You are always capable of improving yourself, and there's always room for improvement.

We explain in this video how the Management decision-making process works. We'll discuss the different types and reasons they are important. Managers should also know how to navigate them. These topics are covered in this course:

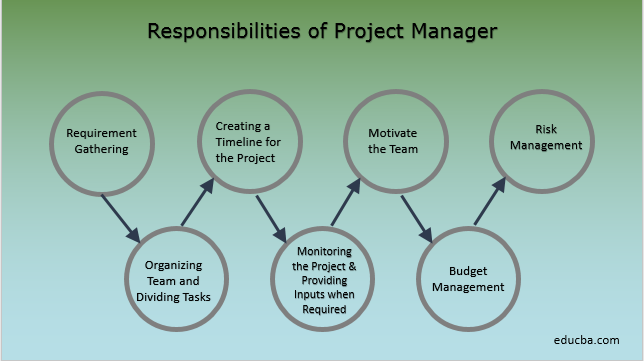

Why is project management important for companies?

Project management techniques ensure that projects run smoothly while meeting deadlines.

Because most businesses depend heavily on project work to produce goods or services,

These projects require companies to be efficient and effective managers.

Companies may lose their reputation, time and money if they do not have effective project management.

What role should a manager play within a company

Each industry has a different role for a manager.

The manager oversees the day-to-day activities of a company.

He/she will ensure that the company fulfills its financial obligations.

He/she will ensure that employees follow all rules and regulations, and adhere to quality standards.

He/she oversees marketing campaigns and plans new products.

Statistics

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

External Links

How To

How do I do the Kaizen Method?

Kaizen means continuous improvement. The Japanese philosophy emphasizes small, incremental improvements to achieve continuous improvement. This term was created by Toyota Motor Corporation in 1950. It's where people work together in order to improve their processes constantly.

Kaizen is one the most important methods of Lean Manufacturing. This concept requires employees to identify and solve problems during manufacturing before they become major issues. This way, the quality of products increases, and the cost decreases.

Kaizen is the idea that every worker should be aware of what is going on around them. To prevent problems from happening, any problem should be addressed immediately. If someone spots a problem while at work, they should immediately report it to their manager.

Kaizen has a set of basic principles that we all follow. When working with kaizen, we always start with the end result and move towards the beginning. We can improve the factory by first fixing the machines that make it. Then, we fix the machines that produce components and then the ones that produce raw materials. Then we fix the workers, who directly work with these machines.

This is why it's called "kaizen" because it works step-by-step to improve everything. Once the factory is fixed, we return to the original site and work our way back until we get there.

You need to know how to measure the effectiveness of kaizen within your business. There are several ways to determine whether kaizen is working well. Another way to determine if kaizen is working well is to look at the quality of the products. Another way to find out how productive your company has been since you implemented kaizen is to measure the increase in productivity.

A good way to determine whether kaizen has been implemented is to ask why. It was because of the law, or simply because you wanted to save some money. Did you really believe it would lead to success?

Suppose you answered yes to any of these questions, congratulations! You're ready to start kaizen.